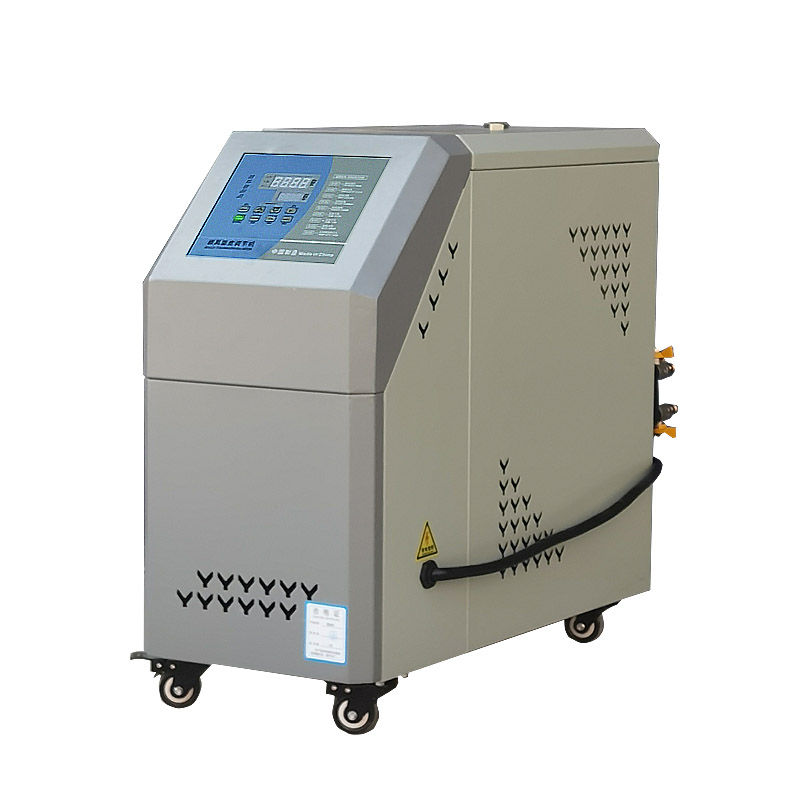

This 12KW Oil Type Mold Temperature Controller is the most popular model in various industries, with stable performance, affordable price, and one year warranty for the whole machine. Mold temperature machine, also known as mold thermostat, was originally used for heating and constant temperature equipment for injection molds. Later, with the development of the machinery industry, the application became more and more extensive.

Now it can be used in various industries such as plastic molding, die-casting, rubber tires, rollers, chemical reaction kettles, bonding, and internal mixing. In a broad sense, it is called temperature control equipment, which includes two control functions of heating and constant temperature.

Mold temperature controllers can be divided into water temperature controllers and oil temperature controllers. The temperature control range of water type mold temperature controllers is 30-180℃, and the temperature control range of oil type mold temperature controllers is 30-350℃. The temperature control accuracy can reach±0.1℃.

|

Model |

Unit |

(water)JSSW-06 |

(water)JSSW-09 |

(water)JSSW-12 |

(water)JSSW-18 |

(water)JSSW-24 |

(water)JSSW-36 |

|

Unit |

(oil)JSYW-06 |

(oil)JSYW-09 |

(oil)JSYW-12 |

(oil)JSYW-18 |

(oil)JSYW-24 |

(oil)JSYW-36 |

|

|

Temperature control range |

℃ |

water:±30℃—120℃/±20℃—180℃,oil:±30℃—180℃/±30℃—350℃ |

|||||

|

Temperature control accuracy |

|

PID±1℃ |

|||||

|

power supply |

|

AC 5φ380V 50HZ 3P+E ( 5M ) |

|||||

|

Heat transfer media |

|

WATER/Thermal oil |

|||||

|

cooling method |

|

Direct cooling/indirect cooling |

|||||

|

heating power |

KW |

6 |

9 |

12 |

18 |

24 |

36 |

|

Pump horsepower |

HP |

1/2 |

1/2 1 |

1 |

1 |

2 |

3 |

|

Pump working flow |

L/MIN |

42 |

42 56 |

56 |

56 |

110 |

315 |

|

Pump working pressure |

KG/CM² |

0.5 |

0.5 1.0 |

1.0 |

1.0 |

1.5 |

2.5 |

|

Maximum power consumption |

KW |

1.5 |

1.5 4 |

4 |

5 |

11 |

18 |

|

Alarm function |

|

Phase loss/water shortage/over temperature/overload/reverse/high pressure |

|||||

|

Cooling water piping |

INCH |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

|

Circulating oil piping |

INCH |

3/8x2 |

3/8x3 |

3/8x4 |

3/8x4 |

3/8x4 |

1-1/2 |

|

Dimensions |

MM |

680x330x570 |

680x330x570 |

760x390x580 |

760x390x580 |

910x510x710 |

910x510x710 |

|

weight |

KG |

60 |

65 |

160 |

170 |

180 |

210 |

1. Mold temperature controller can be divided into water temperature controller and oil temperature controller. The temperature control range of water type mold temperature controller is 30-180℃, and the temperature control range of oil type mold temperature controller is 30-350℃. The temperature control accuracy can reach ±0.1℃;

2. The microcomputer touch operation is simple;

3. Automatic exhaust after starting;

4. Display of outlet and return water temperature;

5. Mold backwater function (optional);

6. 304 stainless steel pipe, reduce pipe shadow and rust;

7. Failure display, no need for professional maintenance.

Conventional water heating series power 6KW-48KW, temperature 30℃-120℃;

The power of conventional oil heating series is 6KW-48KW, and the temperature is 30℃-180℃;

High temperature water heating series power 36KW-120KW temperature 120℃-180℃;

The power of high temperature oil heating series is 36KW-120KW, and the temperature is 250℃-350℃.

Abstract: This is a high-quality 12KW Oil Type Mold Temperature Controller, using 100% real 304 stainless steel heating tube, 304 stainless steel seamless steel heating tube, French Schneider Electric, and using all-brass branded pumps with good sealing properties. Use the heating tube with sufficient power to ensure rapid temperature rise and constant temperature stability.

Q1: Are you a manufacturer?

A1: Yes, we have 20 years of manufacturing experience. We are located in Renzhou Industrial Zone, Shatian Town, Dongguan City, Guangdong Province, China.

Q2: Can you help us recommend a model suitable for our project?

A2: Yes, we have engineers professionally calculate for you, and reasonably recommend the machine suitable for your use. Our engineers can check the details and make the structure. Based on the following points: 1) function recommendation; 2) power matching; 3) size determination 4) voltage recommendation; 5) applicable industry 6) machine drawings (if any) 7) other special requirements, etc.

Q3: How to ensure that your products are of good quality?

A3: We use core components for international brand accessories, such as French Schneider Electric, etc. The configuration devices have been load tested to ensure good quality and easy installation for users.

Q4: How long is the 12KW Oil Type Mold Temperature Controller warranty period?

A4: Counting from the date of production and leaving the factory, the free warranty is within one year. If both parties confirm that the damage is caused by quality reasons, a 12-month free warranty will be provided.

Q5: What is your payment method?

A5: We accept T/T, L/C, Western Union money transfer. By wire transfer and other methods, a 50% deposit is required for production, and the balance is paid before shipment.

Q6: Can you design for us?

A6: Yes, we can customize production according to user requirements.

Q7: What is the lead time for production?

A7: Standard model machines are available in stock, and they will be shipped from the factory within 2 days after receipt. The production cycle of non-standard customized models is determined by the actual quantity. Generally, non-standard products will be delivered within 25 working days after receiving the deposit.

A. We have 20 years of production technology experience.

B. We can provide you with more suitable solutions.

C. Can provide you with multiple requirements for customized services

D. Stable quality + fast delivery time + reasonable price + strong technical support + intimate after-sales service

E. Our company has CE certification

Mass production of 12KW Oil Type Mold Temperature Controller

Our certificates:

Thank you for your patience to read!

If you need to inquire about prices and technical questions, please call 13925748878 Miss Zhu or click on customer service to answer you, we will provide you with the best quality service.